Structural works

With the walls of the basement all lowered and supported the next step could begin. The remaining soil was removed, excavate & cast a sump in place, level the floor and compact it to give a firm base. Timber was fitted around the perimeter of the basement to form a drainage channel. This channel allows incoming water to be directed to the sump & pumping station.

A layer of plastic was then laid to prevent the new concrete dying out too fast. On top of this the steel reinforcing as drilled into the concrete underpinning. Steel reinforcing mesh was laid tying together the walls and floor.

Levelling rails were installed and finally the concrete was cast, completing the new structure.

Waterproofing

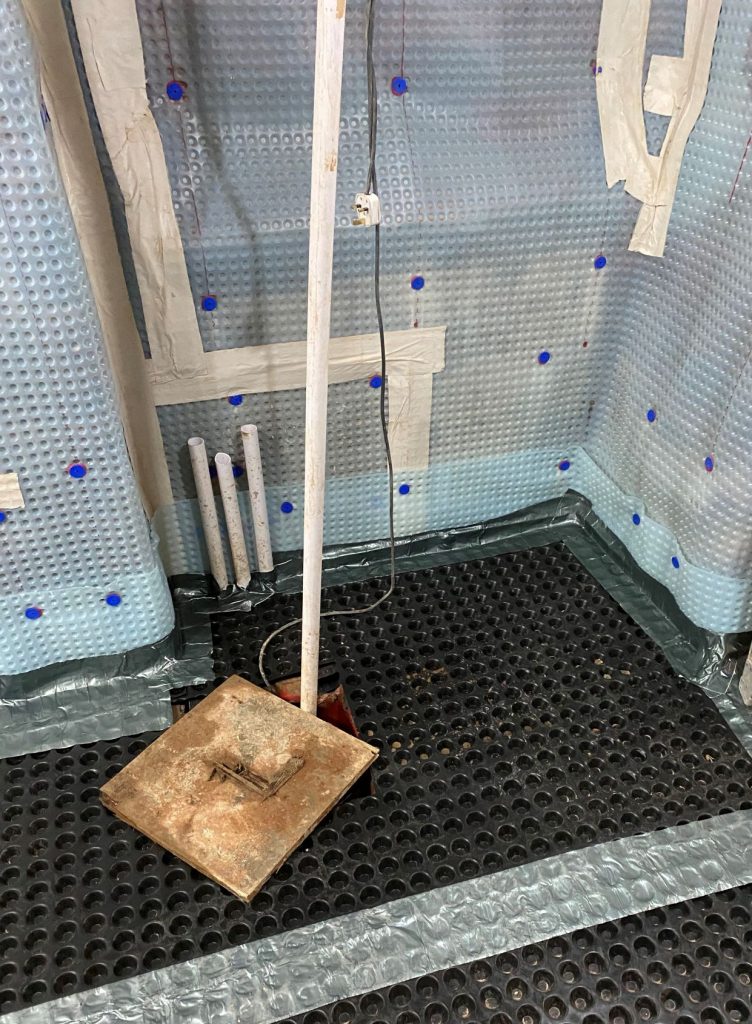

The basement was waterproofed using a Type C, Drained Cavity System. Supplied by Triton Systems. The cavity drainage membranes on the walls and floor were linked via the perimeter drains to a sump and pumping station, which would discharge all water automatically.

Once complete the basement could be insulated, dry lined and finished to the specifications set out by the clients.